Characteristics of dry-type transformers

Dry-type transformer: rely on air convection for cooling, generally used for local lighting, electronic circuits, mechanical equipment and other transformers.

In the power system, generally steam turbine transformers, boiler transformers, ash removal transformers, dust removal transformers, desulfurization transformers, etc. are all dry type transformers, with transformation ratios of 6000V/400V and 10KV/400V, used for loads with a rated voltage of 380V.

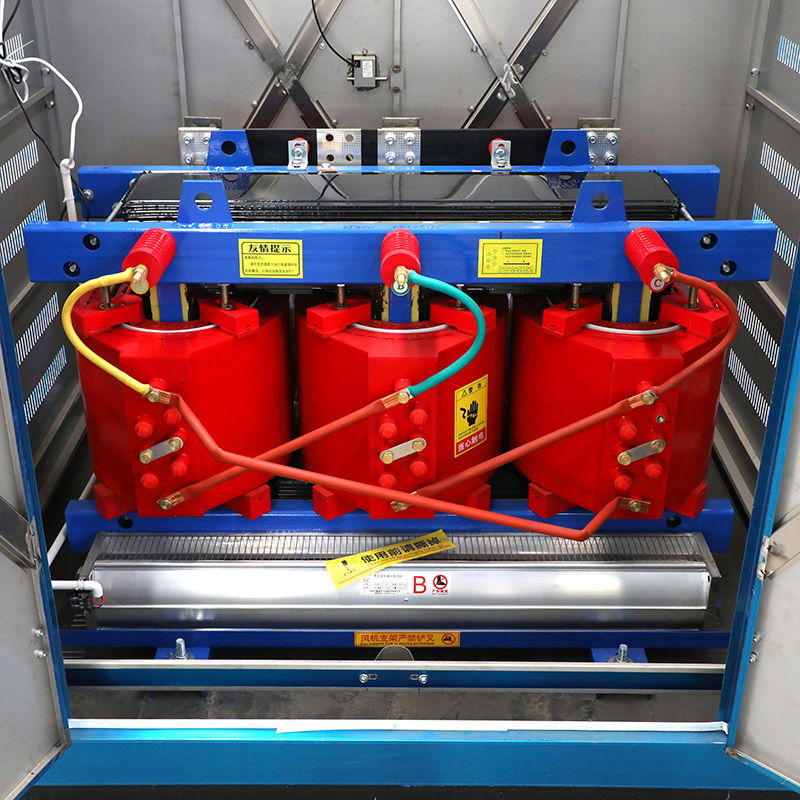

Simply put, a dry-type transformer refers to a transformer in which the iron core and winding are not immersed in insulating oil.

Dry-type transformer structure type:

(1) Encapsulated winding with solid insulation;

(2) The winding without encapsulation.

Of the two windings, the higher voltage is the high voltage winding and the lower voltage is the low voltage winding.

The winding form is generally poured with glass fiber-reinforced epoxy resin, which can effectively prevent the poured resin from cracking and improve the reliability of the equipment.

Temperature Control System of Dry Type Transformer

The safe operation of a dry-type transformer and its service life largely depends on the safety and reliability of the transformer winding insulation. The insulation damage caused by the winding temperature exceeding the insulation tolerance temperature is one of the main reasons for the transformer not working normally. Therefore, it is very important to monitor the operating temperature of the transformer and its alarm control.

Protection methods for dry-type transformers

According to the characteristics of the use environment and protection requirements, different shells can be selected for dry-type transformers. Usually, IP23 protective shell is used to prevent the entry of solid foreign objects with a diameter larger than 12mm and small animals such as rats, snakes, cats, and sparrows, which may cause vicious failures such as short-circuit power failures and provide a safety barrier for live parts. If the transformer must be installed outdoors, an IP23 protective enclosure can be selected. In addition to the above-mentioned IP20 protection function, it can also prevent water dripping within 60° from the vertical line. However, the IP23 enclosure will reduce the cooling capacity of the transformer, so attention should be paid to the reduction of its operating capacity when selecting it.

Cooling method of dry-type transformer

Dry-type transformer cooling methods are divided into natural air cooling (AN) and forced air cooling (AF). When naturally air-cooled, the transformer can operate continuously for a long time at the rated capacity. When forced air cooling, the output capacity of the transformer can be increased by 50%. It is suitable for intermittent overload operation or emergency accident overload operation; due to the large increase in load loss and impedance voltage during overload, it is in a non-economic operation state, so it should not be used for long-term continuous overload operation.

Overload capacity of dry-type transformers

The overload capacity of a dry-type transformer is related to the ambient temperature, the load before overload (initial load), the insulation and heat dissipation of the transformer, and the heating time constant. If necessary, you can ask the manufacturer for the overload curve of the dry transformer.

Technical parameters of dry-type transformers

1. Frequency of use: 50 / 60HZ;

2. No-load current: < 4%;

3. Dielectric strength: 2000V/min without breakdown; test instrument: YZ1802 pressure tester (20mA);

4. Insulation grade: F grade (special grade can be customized);

5. Insulation resistance: ≥2M ohm test instrument: ZC25B-4 type megger <1000 V);

6. Connection mode: Y/Y, △/Y0, Yo/△, self-coupling (optional);

7. Allowable temperature rise of the coil: I00K;

8. Heat dissipation method: natural air cooling or temperature-controlled automatic heat dissipation;

9. Noise coefficient: ≤30dB.

The working environment of a dry-type transformer

0 - 40 ℃, relative humidity < 80%

Altitude: no more than 2500 meters.

Protect from rain, moisture, heat, heat, or direct sunlight. There should be a distance of not less than 40cm between the cooling vents and the surrounding objects.

Avoid working in places with corrosive liquids, gases, dust, conductive fibers, or metal fines.

Avoid working in places with vibration or electromagnetic interference.

Avoid long-term upside-down storage and transportation, and avoid strong impact.

The future of dry-type transformer development

With the promotion and application of dry-type transformers, its production and manufacturing technology has also achieved considerable development. It can be predicted that future dry-type transformers will be further developed in the following aspects:

(1) Energy saving and low noise: With the introduction of new low-consumption silicon steel sheet, foil winding structure, stepped iron core joints, environmental protection requirements, noise research, computer optimization design and other new materials, new processes, and new technologies, It will make future dry-type transformers more energy-efficient and quieter.

(2) High reliability: Improving product quality and reliability will be the relentless pursuit of people.

(3) Environmental protection certification: Based on the European standard HD464, carry out research and certification of dry-type transformers' weather resistance (C0, C1, C2), environment resistance (E0, E1, E2), and fire resistance (F0, F1, F2) characteristics.

(4) Large capacity: from 50-2500kVA distribution transformer-based dry-type transformers to 10000-20000kVA/35kV power transformers, as the city's electricity load continues to increase, urban network regional substations are getting deeper and deeper into urban centers, Residential quarters, large factories and mines and other load centers, 35kV large-capacity community center power supply transformers will be widely used.

(5) Multi-functional combination: from a single transformer to a multi-functional combined transformer with air cooling, protective casing, temperature computer interface, zero-sequence transformer, power metering, closed busbar, and side outlet.

(6) Multi-field development: From distribution transformers as the mainstay to special transformers and multi-purpose fields such as power station transformers, excitation transformers, subway traction rectifier transformers, high-current electric furnace transformers, nuclear power plants, ships, and oil production platforms. Among them, dry-type traction transformers used in urban subways and rail transit have three levels of voltage: 10, 20, and 35kV, and capacities of 800, 2500, and 3300kVA. In order to reduce harmonic pollution, the rectification has been developed from 12 pulses to 24 pulses Rectification; the excitation transformer of the world's largest 840,000kW generator in the Three Gorges of the Yangtze River, which has attracted worldwide attention, has been successfully developed by Shunte Factory and passed the national acceptance.

It can be predicted that distribution transformers in the 21st century will belong to resin-insulated dry-type transformers with superior performance, low noise, and energy saving.